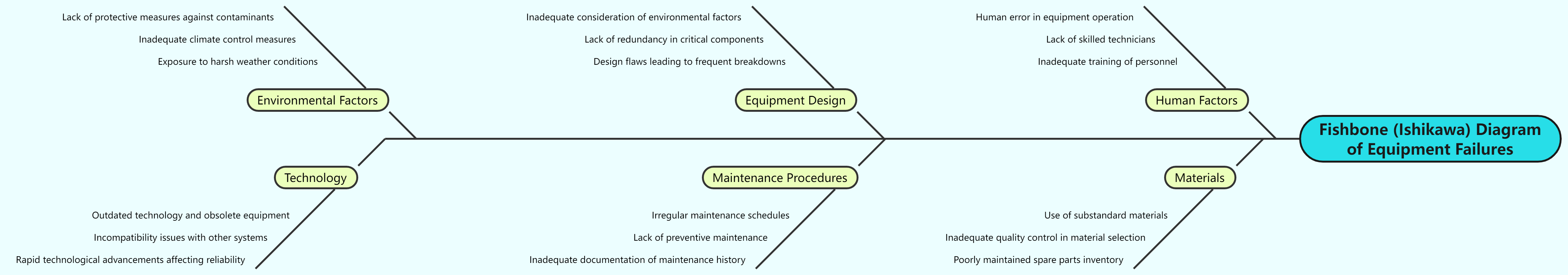

A Comprehensive Look at Factors Impacting Equipment Reliability

The Fishbone (Ishikawa) Diagram on Equipment Failures explores interconnected factors contributing to machinery breakdowns, categorized into six key areas. Human Factors encompass inadequate training, a lack of skilled technicians, and errors in equipment operation. Materials-related challenges involve substandard materials, poor quality control, and a neglected spare parts inventory. Equipment Design issues range from design flaws to the absence of redundancy and oversight of environmental factors. Maintenance Procedures include irregular schedules, insufficient preventive maintenance, and inadequate documentation. Environmental Factors consider exposure to harsh conditions, lacking climate control, and insufficient protection against contaminants. Finally, Technology challenges involve outdated systems, compatibility issues, and the rapid pace of technological advancements affecting reliability. This comprehensive analysis underscores the need for a holistic approach to address these multifaceted factors and enhance machinery reliability across various operational contexts.

Proactive Approach to Preventing Equipment Failures

To proactively prevent equipment failures, a robust maintenance strategy is essential. First and foremost, ensuring personnel are adequately trained on equipment operation and maintenance procedures is critical. Establishing a regular and comprehensive maintenance schedule, including preventive measures, helps identify and address potential issues before they escalate. Documentation of maintenance history provides valuable insights into equipment health and aids in predictive maintenance. Utilizing high-quality materials, implementing stringent quality control measures in material selection, and maintaining a well-organized spare parts inventory contribute to equipment longevity. Design considerations should focus on minimizing flaws, incorporating redundancy in critical components, and accounting for environmental factors. Environmental protection measures, such as climate control and safeguards against contaminants, further fortify equipment resilience. Embracing technology upgrades, ensuring compatibility with other systems, and staying abreast of technological advancements mitigate risks associated with outdated equipment. By adopting a holistic and proactive approach, organizations can effectively maintain equipment, prevent failures, and extend the lifespan of their machinery.

Effortless Mind Mapping for Dynamic Collaboration

Creating diverse mind maps with Visual Paradigm Smart Board is a streamlined and user-friendly process. The platform’s intuitive interface empowers users to effortlessly generate a variety of mind maps, including popular formats like Fishbone (Ishikawa) Diagrams. The platform supports dynamic brainstorming sessions, enabling users to organize and visualize ideas interactively. With its comprehensive suite of tools, Visual Paradigm Smart Board facilitates the quick and easy creation of mind maps that can be utilized for strategic planning, problem-solving, and effective communication. Its versatility makes it an ideal solution for professionals seeking an efficient and adaptable tool for visualizing complex concepts and ideas in a collaborative and dynamic environment.