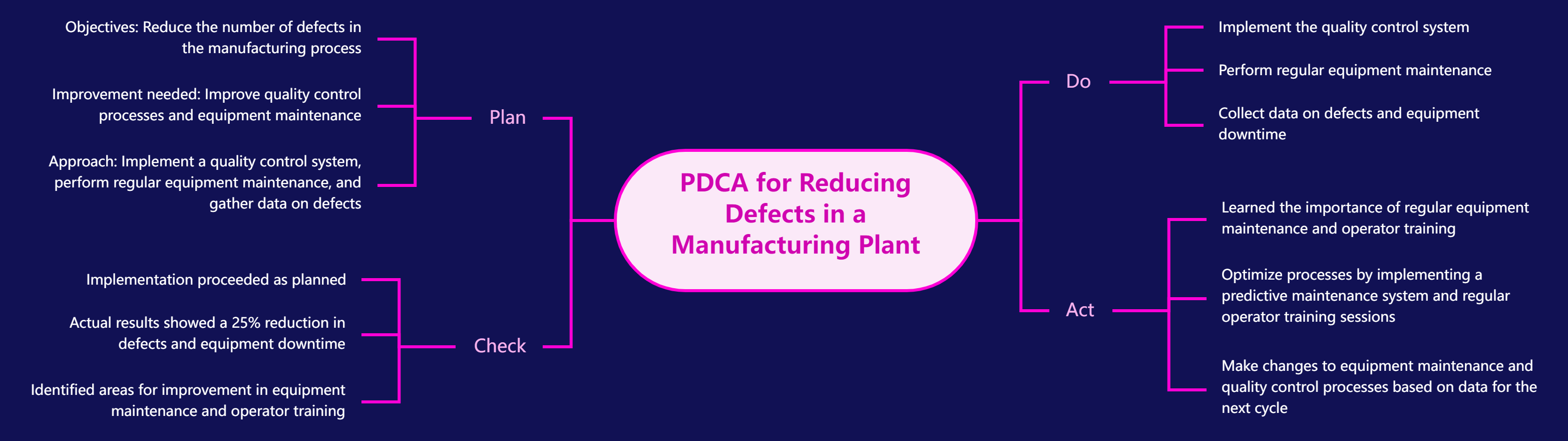

Description of the Mind Map Content

This mind map outlines a PDCA (Plan-Do-Check-Act) cycle aimed at reducing defects in a manufacturing plant. The primary objective is to enhance the overall quality of the manufacturing process. The Plan phase establishes objectives to reduce defects, identifying areas for improvement in quality control processes and equipment maintenance. The Approach involves implementing a quality control system, conducting regular equipment maintenance, and collecting data on defects.

Insights from the Mind Map

In the Do phase, the outlined steps are taken into action. This includes the implementation of the quality control system, regular equipment maintenance, and the collection of data on defects and equipment downtime. The next phase, Check, evaluates the effectiveness of the implemented changes. It is reported that the implementation proceeded as planned, and the actual results demonstrate a significant 25% reduction in defects and equipment downtime. Areas for improvement are identified, particularly in equipment maintenance and operator training.

The Act phase involves learning from the outcomes of the Check phase. Insights gained highlight the importance of regular equipment maintenance and operator training. To optimize processes, the mind map suggests implementing a predictive maintenance system and conducting regular operator training sessions. Changes to equipment maintenance and quality control processes are recommended based on the gathered data, setting the stage for the next PDCA cycle.

Creating Mind Maps with Visual Paradigm Smart Board

The mind map presented here is crafted using Visual Paradigm Smart Board, an intuitive and versatile mind map app. This mind map maker serves as a valuable mind map tool for individuals and teams seeking to enhance their manufacturing processes. Visual Paradigm Smart Board seamlessly integrates online mind map software features, providing a collaborative platform for online brainstorming and facilitating the creation of structured plans like the PDCA cycle. As demonstrated in the outlined PDCA for defect reduction, this tool proves instrumental in efficiently implementing and visualizing improvement strategies. With its user-friendly interface and robust features, Visual Paradigm Smart Board emerges as a practical choice for those looking to elevate their brainstorming and process optimization endeavors.