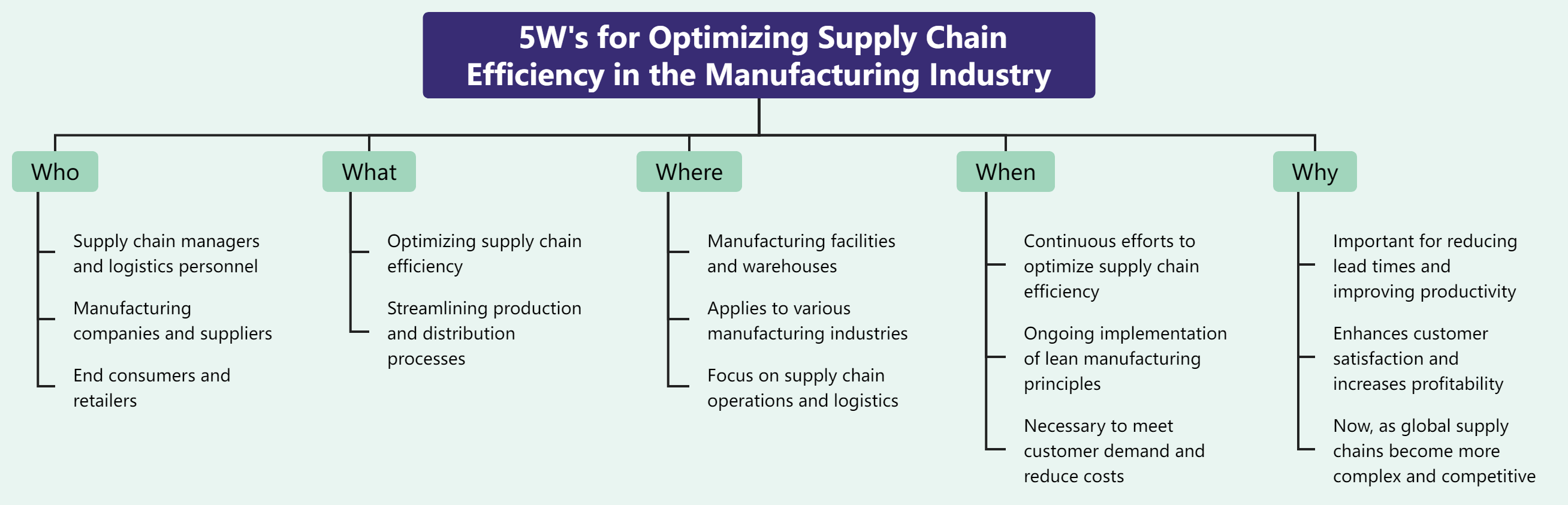

Decoding 5W’s of Supply Chain Optimization in Manufacturing

This mind map revolves around the 5W’s (Who, What, Where, When, Why) of optimizing supply chain efficiency in the manufacturing industry. It identifies key stakeholders, including supply chain managers, logistics personnel, manufacturing companies, suppliers, end consumers, and retailers. The primary focus is on streamlining production and distribution processes in manufacturing facilities and warehouses across various industries. The timing of these efforts is continuous, with an ongoing implementation of lean manufacturing principles. The significance of optimizing the supply chain is highlighted by its importance in reducing lead times, improving productivity, and meeting customer demand while simultaneously reducing costs. The urgency is emphasized by the current global landscape, where supply chains are increasingly complex and competitive, making efficiency a critical factor for success.

Importance of Optimizing Supply Chain Efficiency

Optimizing supply chain efficiency holds paramount importance in the manufacturing industry due to its direct impact on operational excellence, customer satisfaction, and overall business profitability. As global supply chains become increasingly intricate and competitive, streamlining production and distribution processes becomes a strategic imperative. By reducing lead times and improving productivity, manufacturing companies can respond more swiftly to shifting market demands, ultimately enhancing customer satisfaction. Additionally, an optimized supply chain allows for cost reduction through the elimination of inefficiencies, contributing to increased profitability. The adoption of lean manufacturing principles ensures ongoing efforts to enhance efficiency, aligning production with demand and promoting a responsive and agile operational framework. In essence, the quest for supply chain optimization is not merely a competitive advantage but a necessity in the modern industrial landscape, where adaptability and responsiveness are crucial for sustained success.

Navigating the 5W’s with VP Smart Board

Visual Paradigm Smart Board is a professional and versatile tool designed to facilitate the creation of informative and visually engaging mind maps, making it an invaluable asset for efficiently constructing frameworks like the 5W’s. With its user-friendly interface and robust features, Smart Board enables users to seamlessly map out the “Who, What, Where, When, and Why” aspects of a topic. The tool offers a platform for brainstorming and organizing ideas, allowing supply chain professionals and teams to explore and visualize the intricate connections within their processes. Whether used for strategic planning or project management, Visual Paradigm Smart Board stands out as a powerful solution for crafting clear and comprehensive 5W’s mind maps that contribute to enhanced understanding and effective decision-making in the realm of supply chain efficiency optimization.